PCR PLASTIC

Plastic bottle, development / design / manufacturing

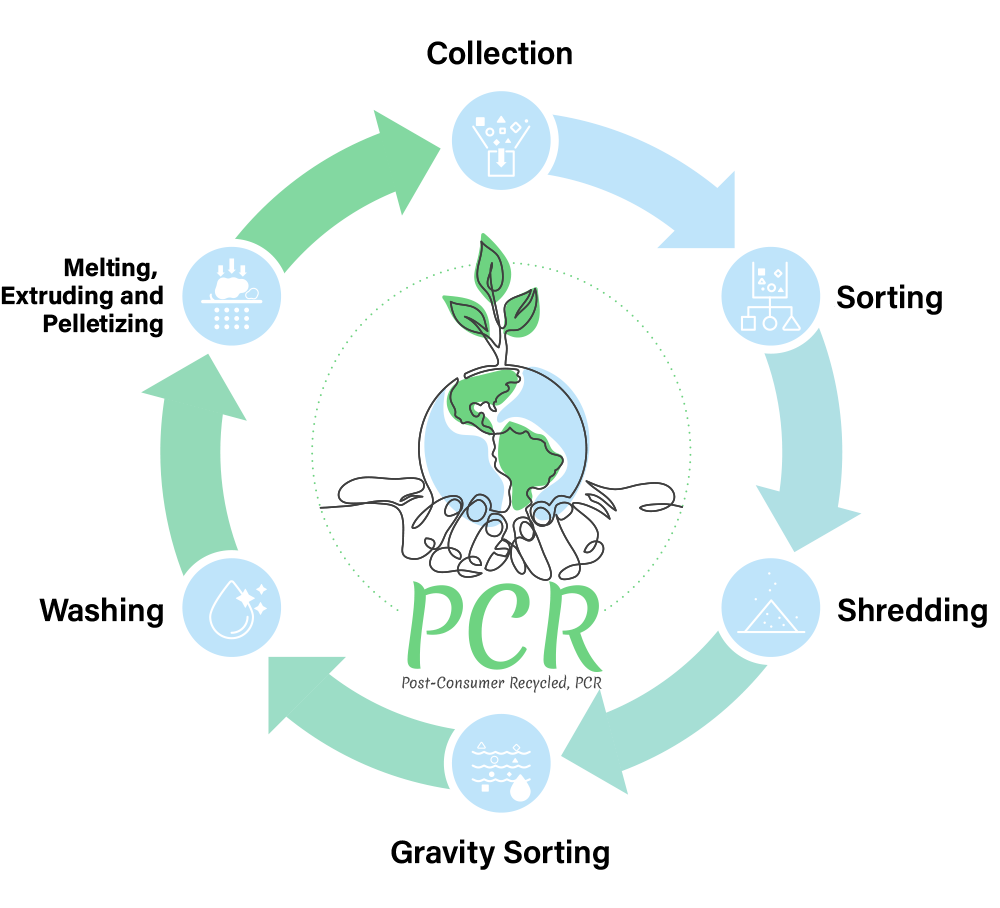

How Does Plastic Waste Become New Product?

01

Collection

Gathering recyclable waste materials and sorting them based on the material they’re made of, including paper, plastic, glass, metal, and more.

02

Sorting

Manual or facilities sort plastic waste into different types of plastic, such as PET, PP, PE, PVC and PS.

03

Shredding

Breaking down the plastic waste into smaller particles or pieces by shredder.

04

Gravity Sorting

Identifying quality of the plastic particles to segregate them based on density by floating them in a container of water.

05

Washing

Washing the plastic particles to remove impurities and everything that is not made from plastic such as product labels and adhesives as well as dirt and food residue.

06

Melting, Extruding and Pelletizing

Melting down the shredded plastic particles and extruding them through an extruder to form pellets, a usable product for manufactures called PCR, Post-Consumer Recycled, plastic.

What Are the Differences Between PCR Plastic Packaging and Virgin(New) Plastic Packaging?

Smell

There is no special smell both in PCR plastic and virgin(new) plastic.

Color

Comparing with virgin(new) plastic, PCR plastic looks slightly yellowish due to recycling production process. Color variation also might be occurred from package to package, but spray painting and coating coloring could help your PCR plastic packages keep standard consistently.

Stability and Compatibility

Both virgin(new) plastic packaging and PCR plastic packaging require to be tested their stability and compatibility by filling materials for a while to make sure the materials are compatible and stable with the selected packaging.

Flexibility

Due to made from recycled materials, PCR plastic packaging will be slightly lesser flexible quality. This issue could be improved through adjusting the molding production setting figure. HeShin ensures our PCR plastic packaging will undergo testing and maintain sufficient durability as our virgin(new) plastic packaging.

English

English